C/Z/Sigma RFM

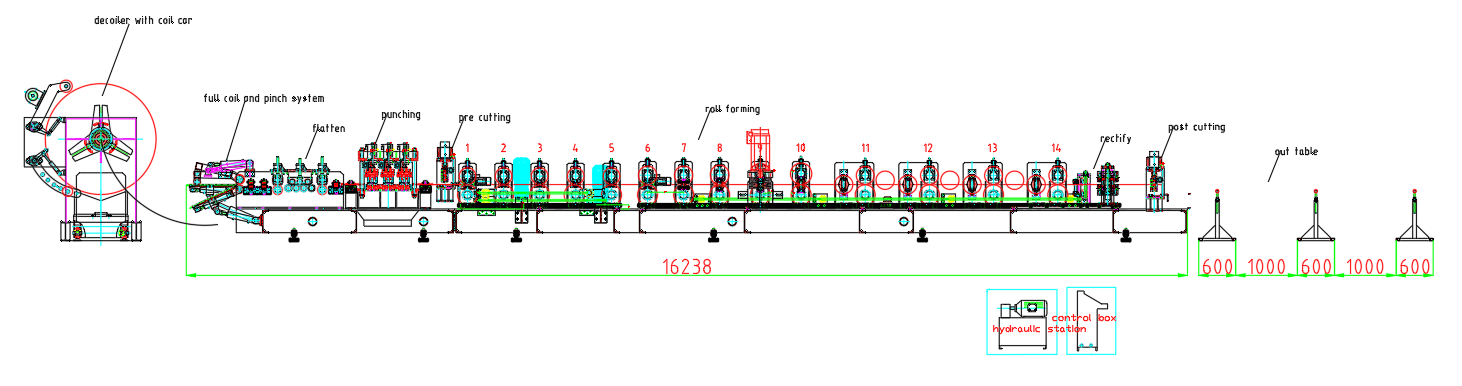

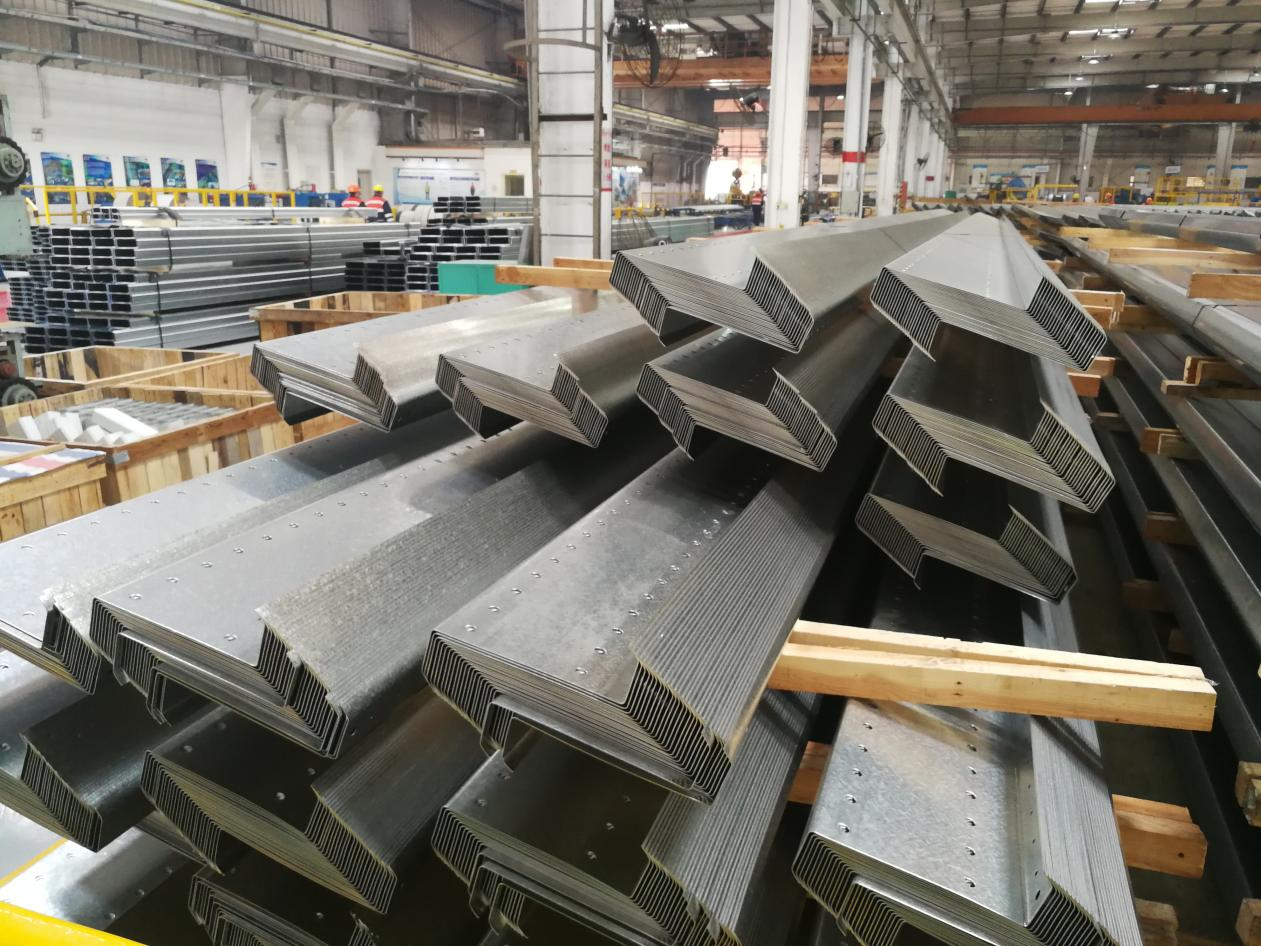

C/Z/Sigma Purlin as one of important section in PEB, in same machine can make C channel, C lip channel, Z purlin and Sigma section. and the web & flange all automatic adjustable by servo motor to get high accuracy. And we give gear box for drive; Change C to Z in automatic also, n a real sense to achieve full automation production

Description

To meet customer different project,Saibo Science & Technology provide different mode in same machine. Here is our two main model size list:

Specification

Model 1:

|

Item |

Minimum |

Maximum |

Comments |

|

Coil Width (mm) |

140 |

540 |

|

|

Web Width Plain Channel |

75 |

300 |

|

|

Web Width |

100 |

300 |

|

|

Flange Height |

40 |

80 |

|

|

Lip Width |

5 |

25 |

At maximum flange height |

|

Lip Angle |

|

90º |

C and Z (45º optional) |

|

Internal Radius |

5 |

|

Nominal |

|

Minimum Length |

1500 |

|

With pre cut |

|

Minimum Length |

10 |

|

With post cut |

|

Steel |

1.0 |

3.0 |

Galvanised/Hotrolled/Prepainted |

Model 2:

|

Item |

Minimum |

Maximum |

Comments |

|

Coil Width (mm) |

140 |

670 |

|

|

Web Width Plain Channel |

75 |

400 |

|

|

Web Width |

100 |

400 |

|

|

Flange Height |

48 |

130 |

|

|

Lip Width |

10 |

32 |

At maximum flange height |

|

Lip Angle |

|

90º |

C and Z (45º optional) |

|

Internal Radius |

5 |

|

Nominal |

|

Minimum Length |

1500 |

|

With pre cut |

|

Minimum Length |

10 |

|

With post cut |

|

Steel |

2.0 |

4.0 |

Galvanised/Hotrolled/Prepainted |

In same machine, we adopt pre cutting and post cutting both option, This is the real solution to the problem of not cutting the short sheet. In this post cutting, no need change the cutters during change size, we called it “Universal cutting”

Main Technology

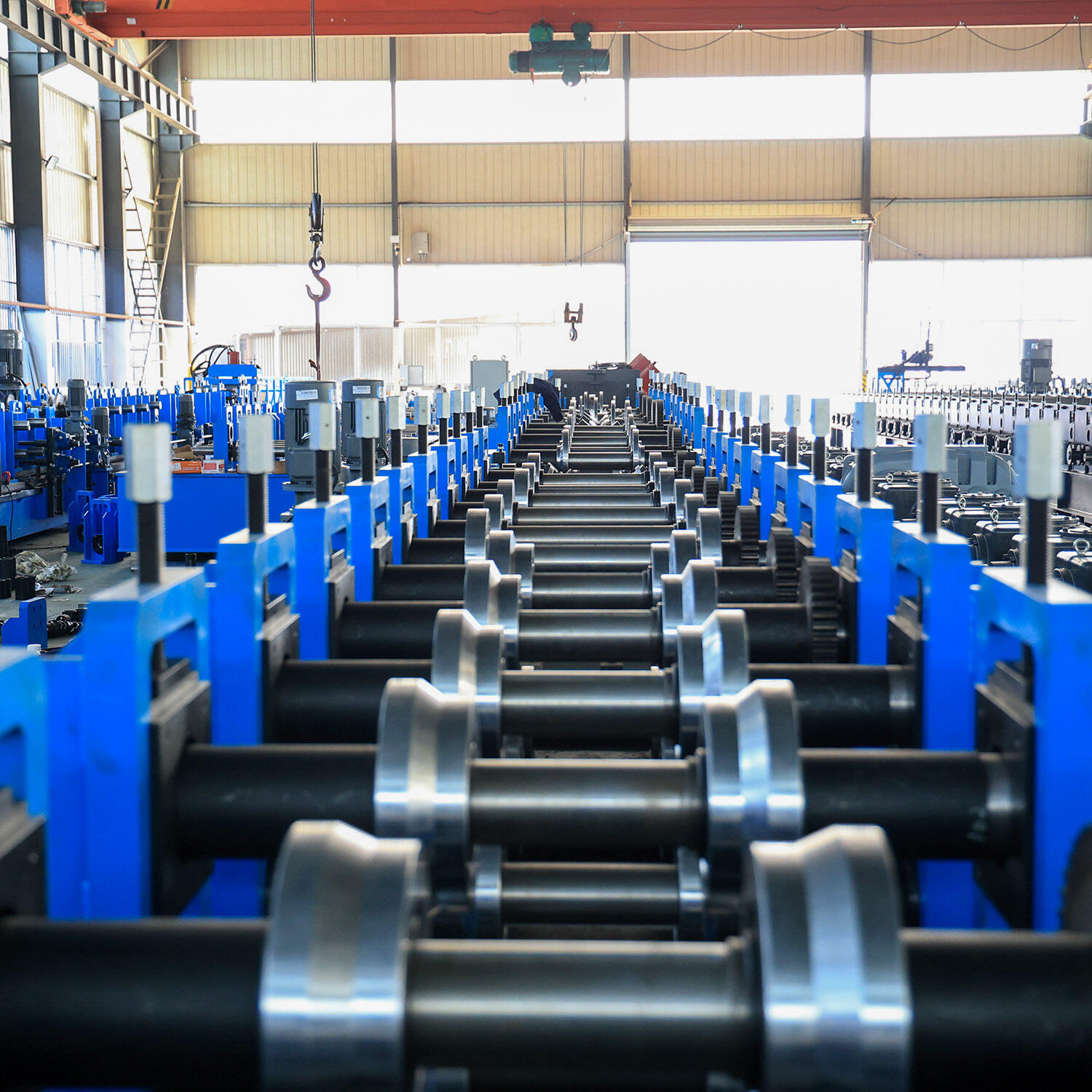

CU-Z purlin is one of main component in PEB project, one machine can make both profile; change C to Z is full automatic, both profile web and flange size is also automatic adjustable by PLC system. Thickness can rolling from 1-4mm by different hardness material.

Main technology

Heavy duty uncoiler with coil car

Full automatic high speed on line punching

Full automatic change C to Z and change size

Non-stop high speed cutting

Full automatic stacking and packing

Main spec. of line:

Full line power: about 90KW

Forming speed:40-50m/min

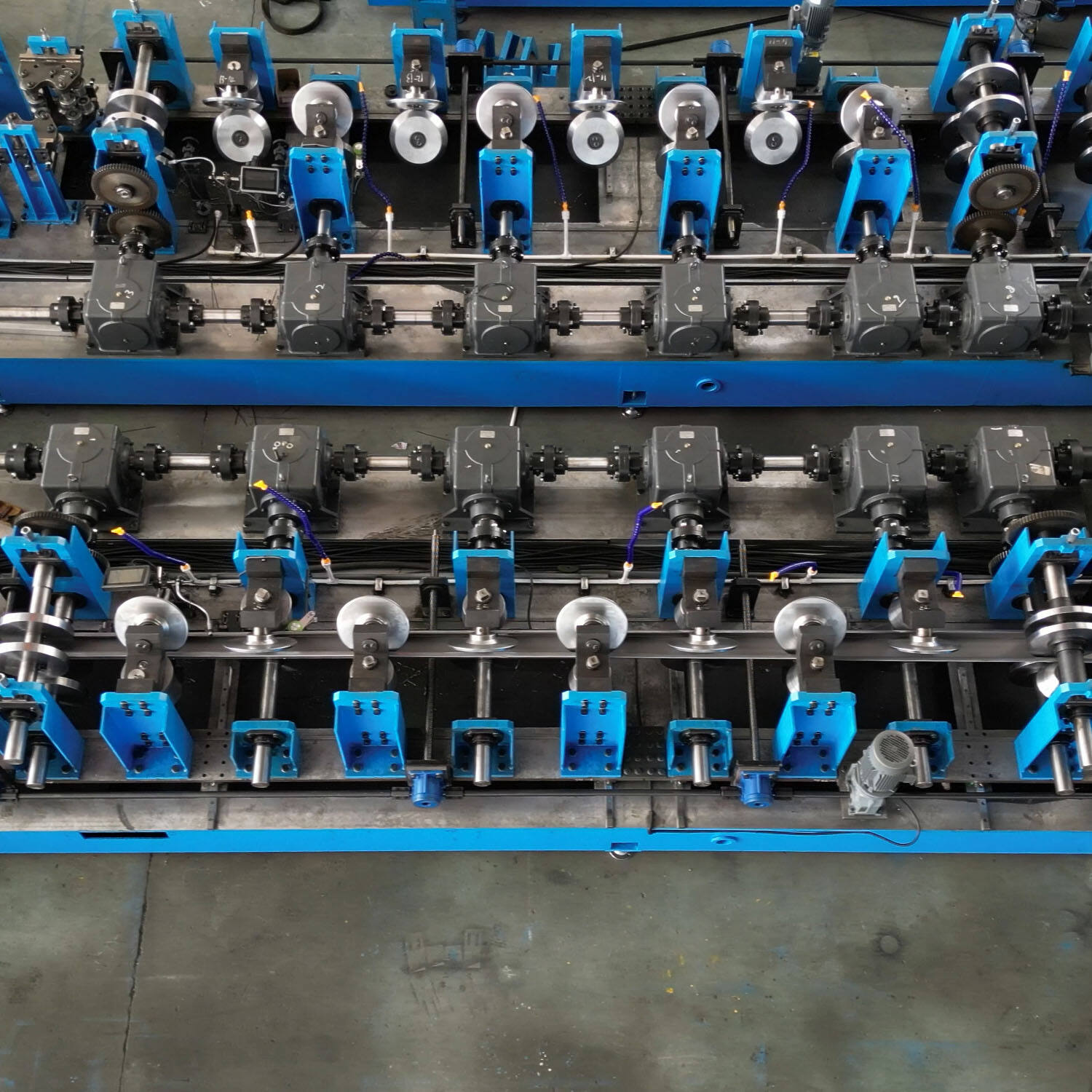

Forming station: about 20 stations

Drive by gear box of each station

Full line weight: about 30Tons

Roller material: D3

Punching die and cutting die material: D2

Motor: Siemens

Servo and control system:Mitsubishi