Railway RFM

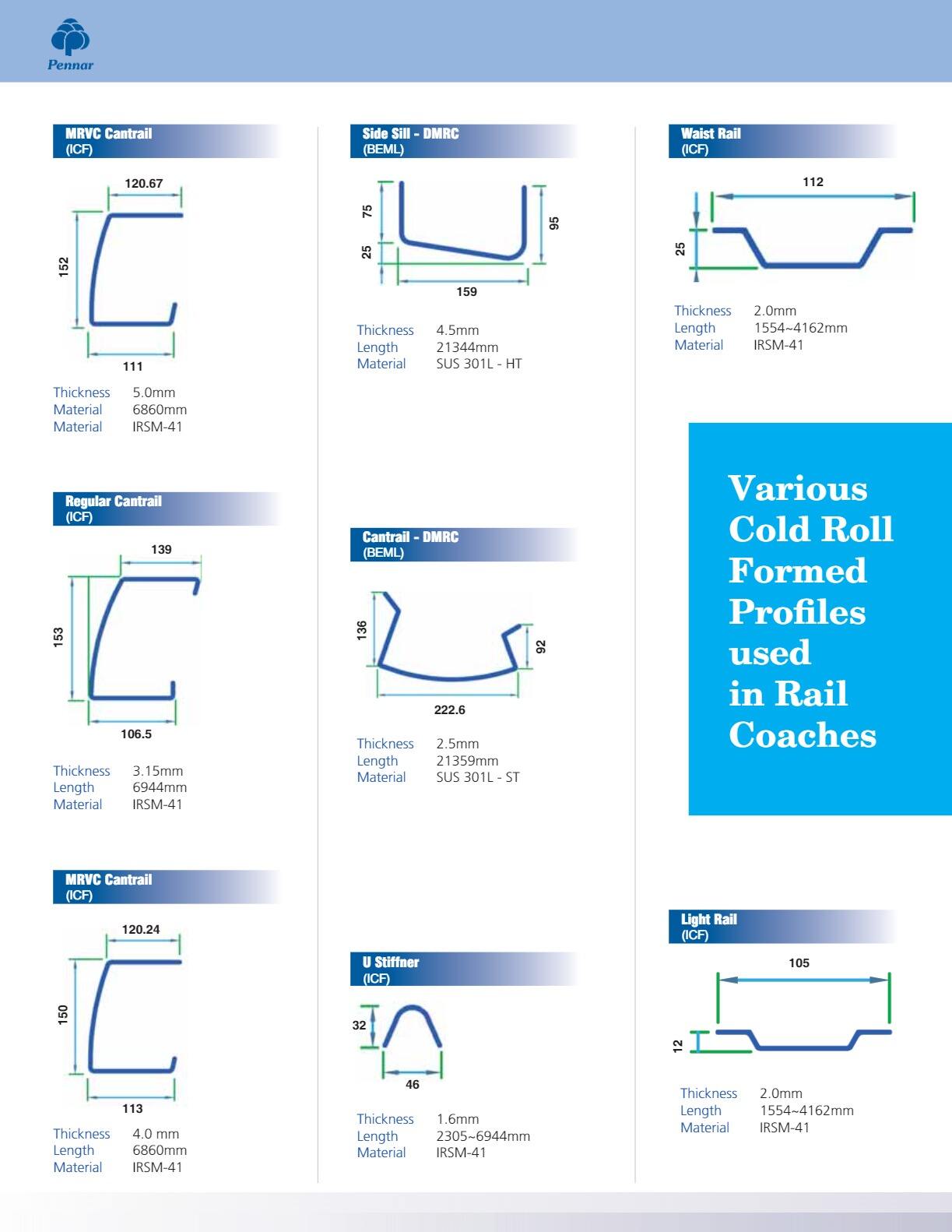

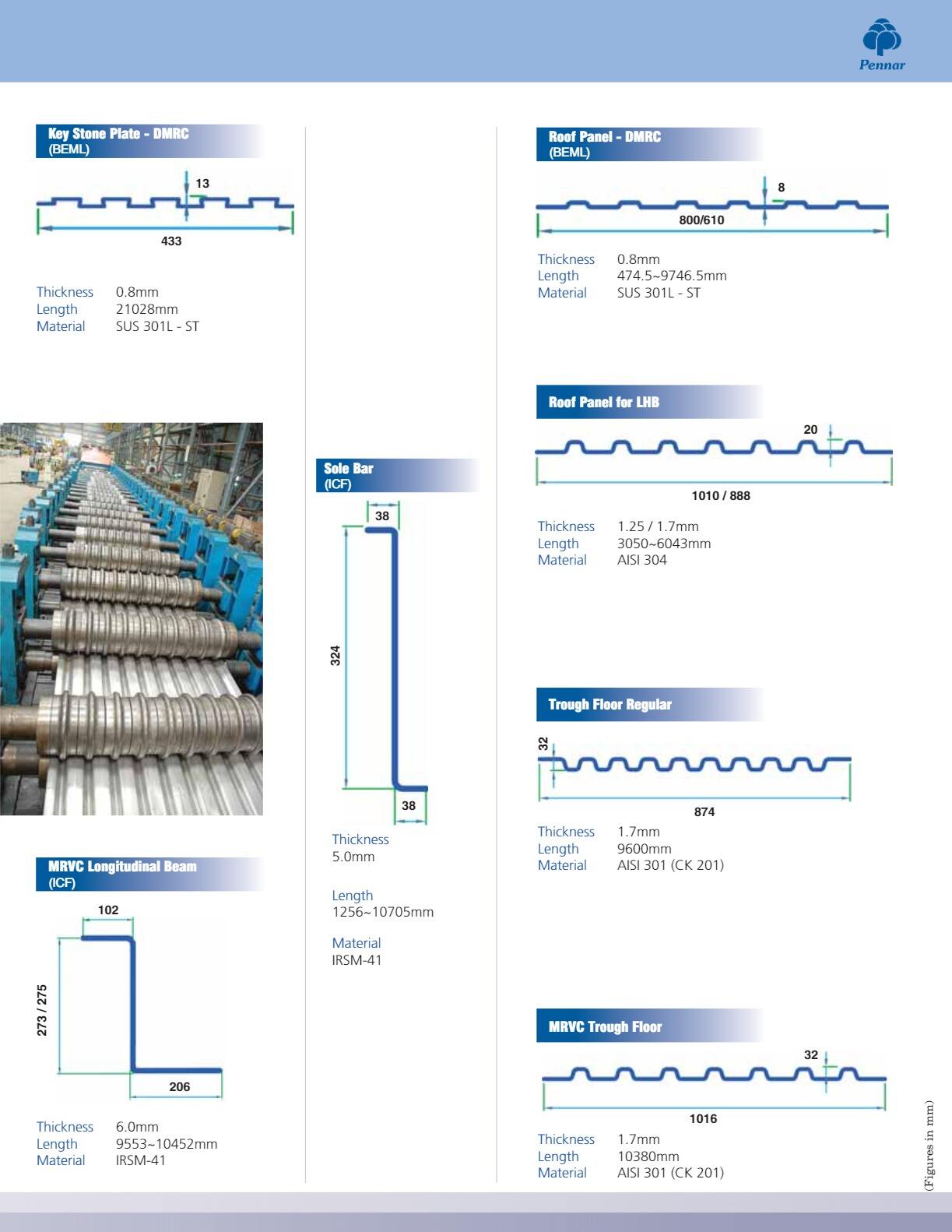

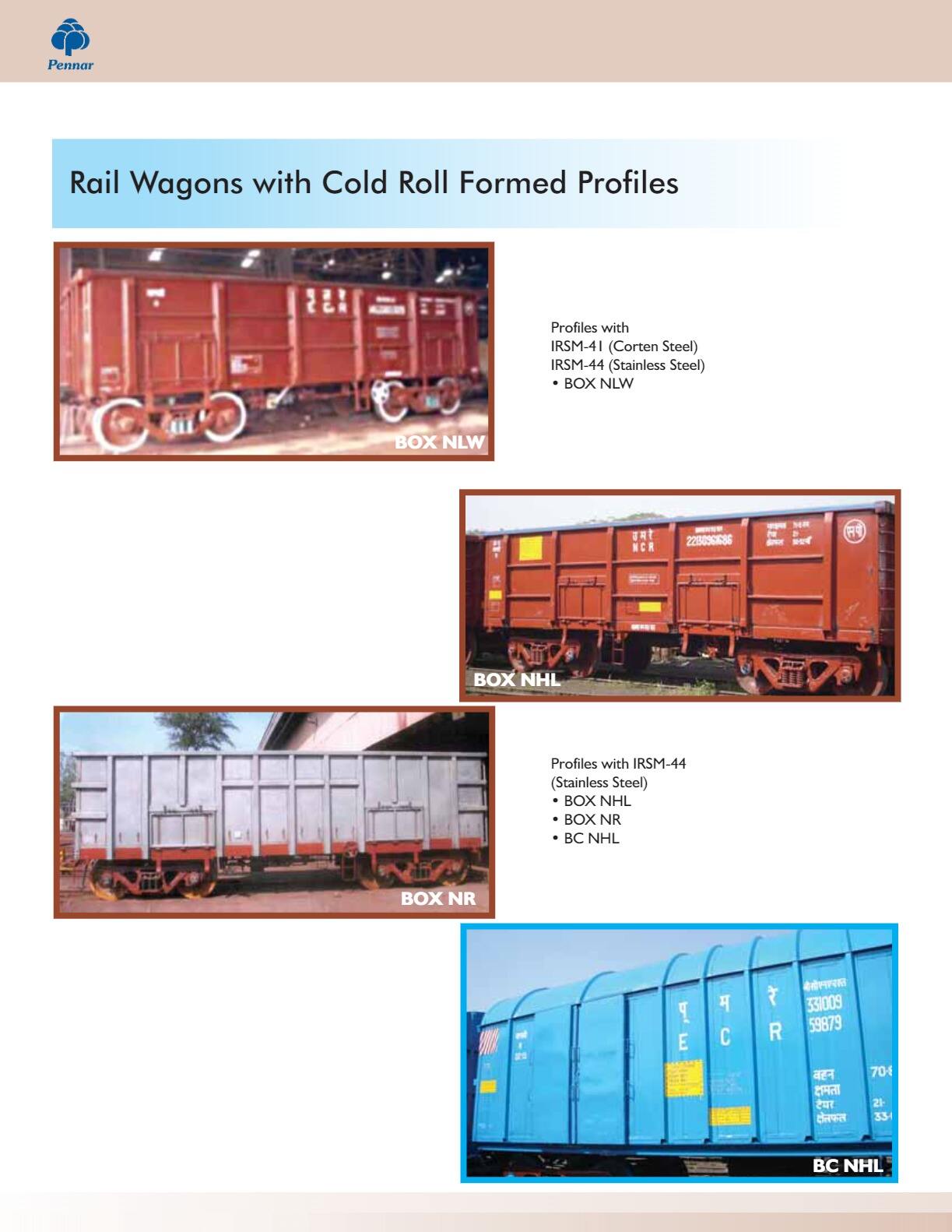

With public transportation facilities assuming greater significance by the day, the requirement of the Railways for railway coaches is also growing exponentially. And, being the mainstay of large-scale goods transportation, so is the need for railway wagons. Saibo Science & Technology provide profiles for railway wagons and coaches machine/fabrication of side walls and roofing assembles for LHB coaches/encoder frame components for coaches and wagons and so on.

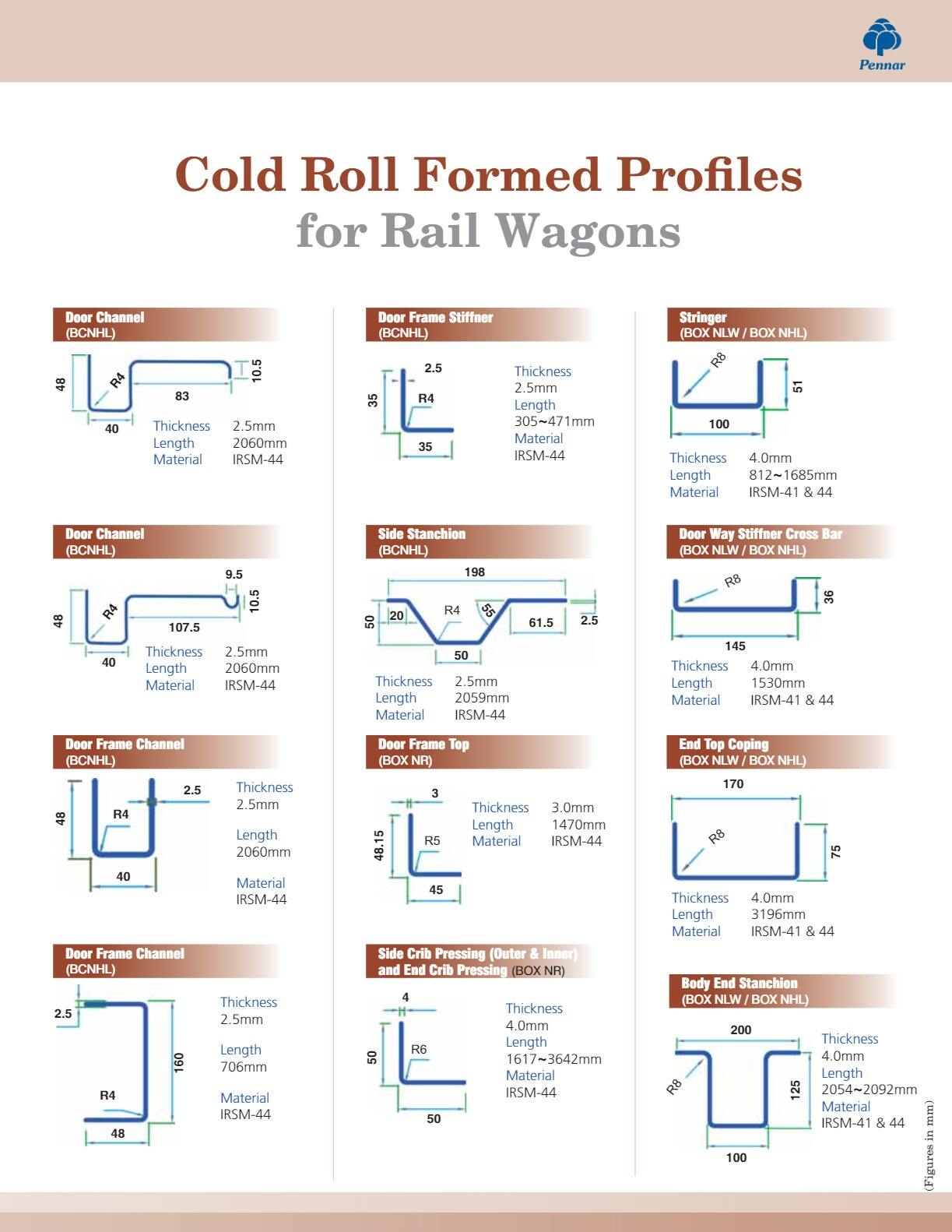

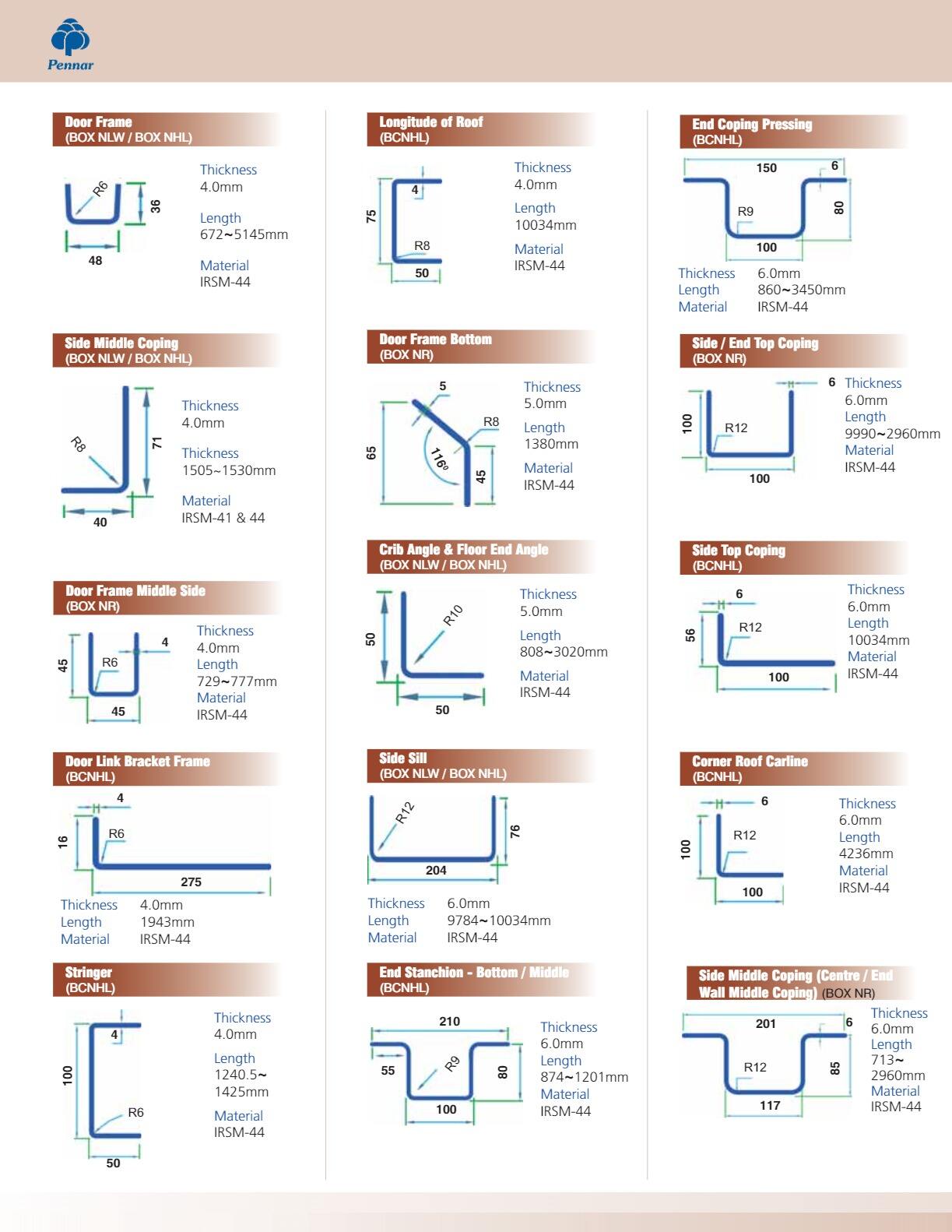

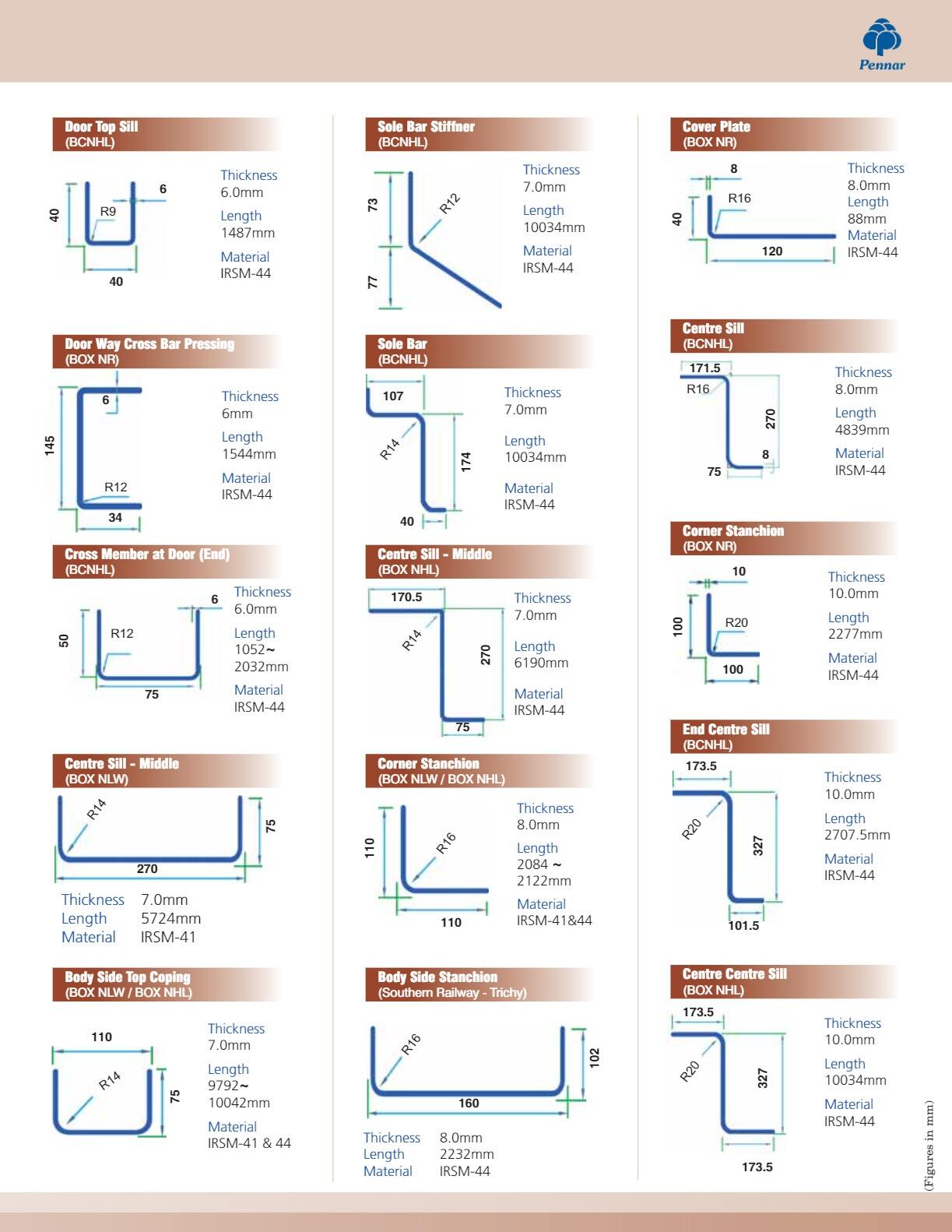

Description

Product Detail

Saibo Science & Technology Railway roll forming machine adopts cassette design, according to customer request, one machine has three cassette units, can produce about 22 kinds of profiles. The rolling material is SS 301, 304, and the thickness range is from 1.25mm to 1.7mm. The forming part is about 7 stations for a quick change, and the replace the cassette units about 1 hour.

Main technology

Heavy duty uncoiler with coil car

Full automatic set request length and quantity

By cassette design one machine can make different profiles

Non-stop high speed cutting

Full automatic stacking and packing

Main spec. of line:

Full line power: about 120KW

Forming speed: 0-15m/min

Forming station: about 15-37 stations

Drive by gear box of each station

Full line weight: about 80-90Tons

Roller material: GCR15

Punching die and cutting die material: D2

Motor: Siemens

Control system: Mitsubishi/ Siemens/Panasonic

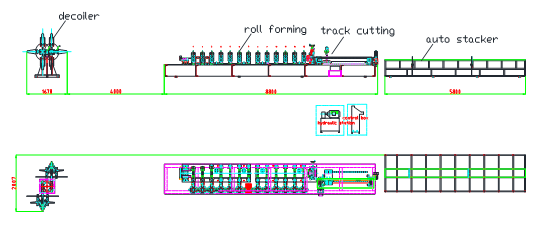

Layout for reference: