Solar Mounting RFM

As one of the new energy sources, solar energy has been vigorously developed in the past ten years, and the demand for solar mounting structures is also increasing day by day.

Description

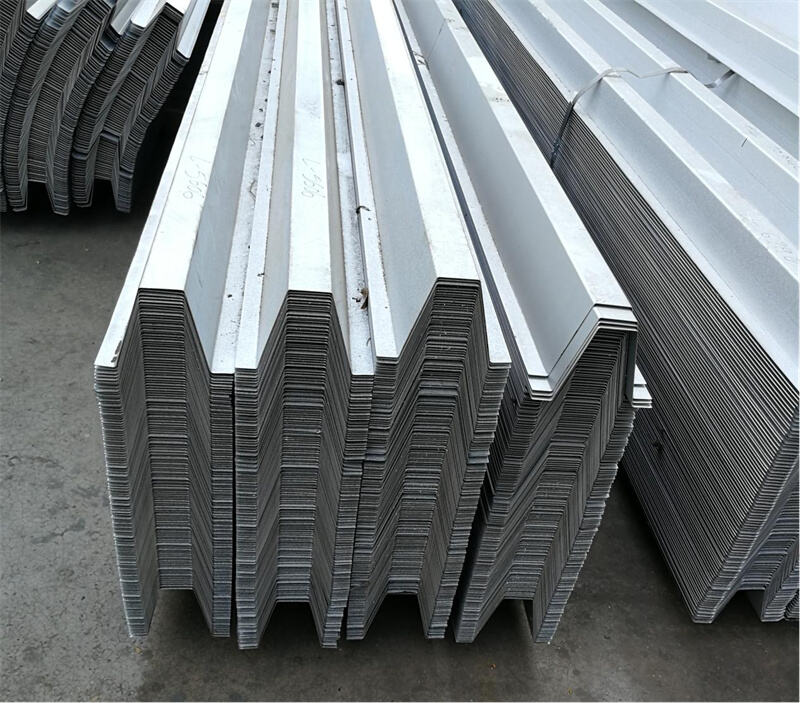

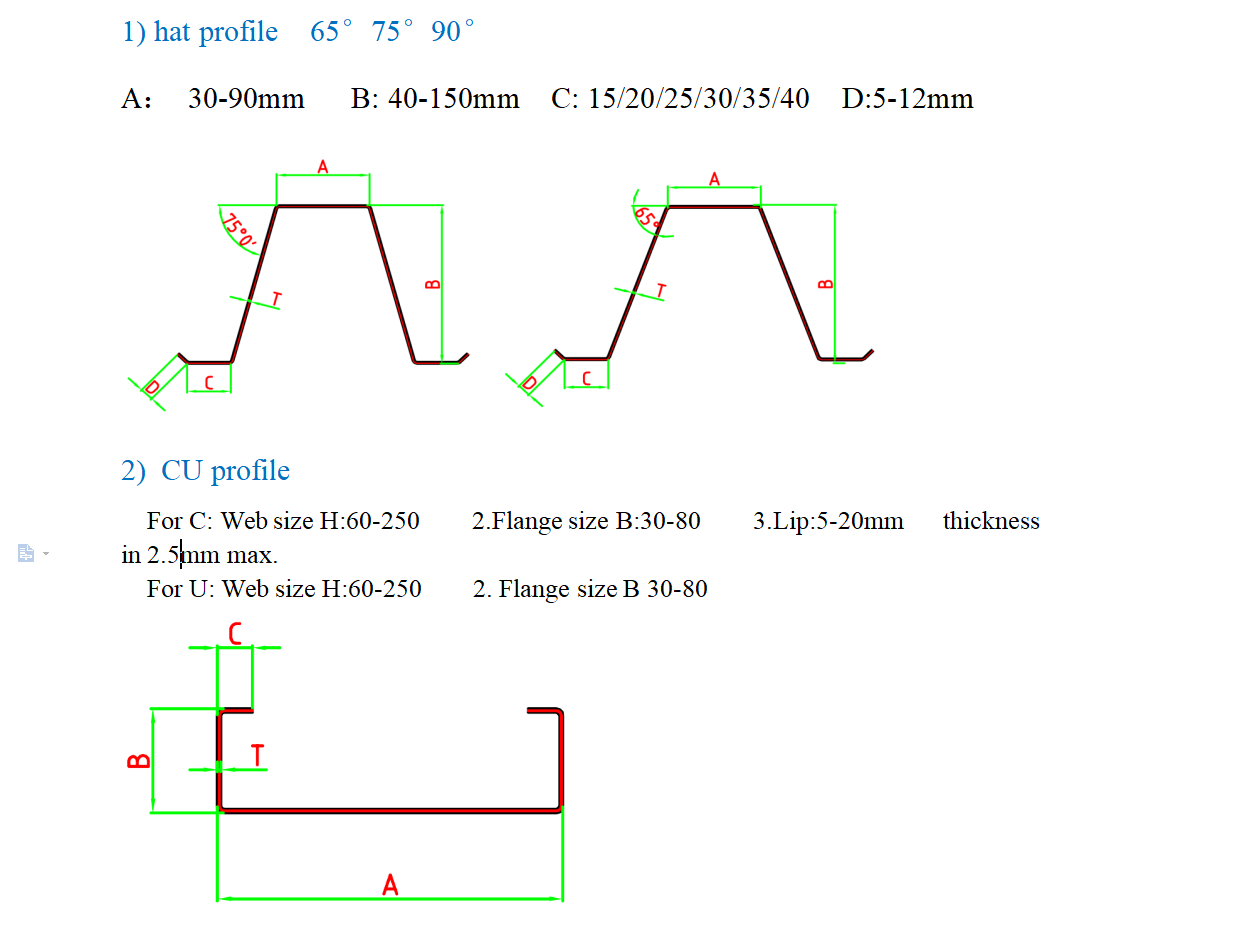

We Provide Mounting Structures Types of Sections:

All of size is AUTOMATIC SMART adjustable

• C Channel

• C Channel with Lip·

• Strut Rail

• Z Channel

• Z Channel with Lip

• Sigma Section

• L Angle

• Hat Section

C and Hat is as one of main component in Solar Mounting, we give one machine can make both profile, just change 10 forming stations, we called it “cassette design”. For C the web/flange/lip all automatic change size; for Hat one machine can make different size and angle. By existing marketing, only our company can make such machine.

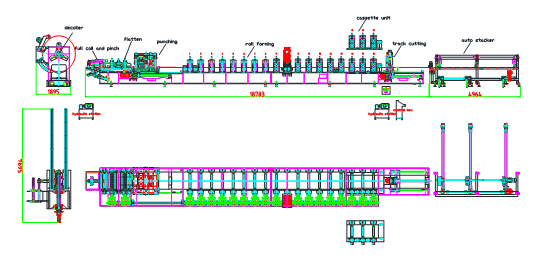

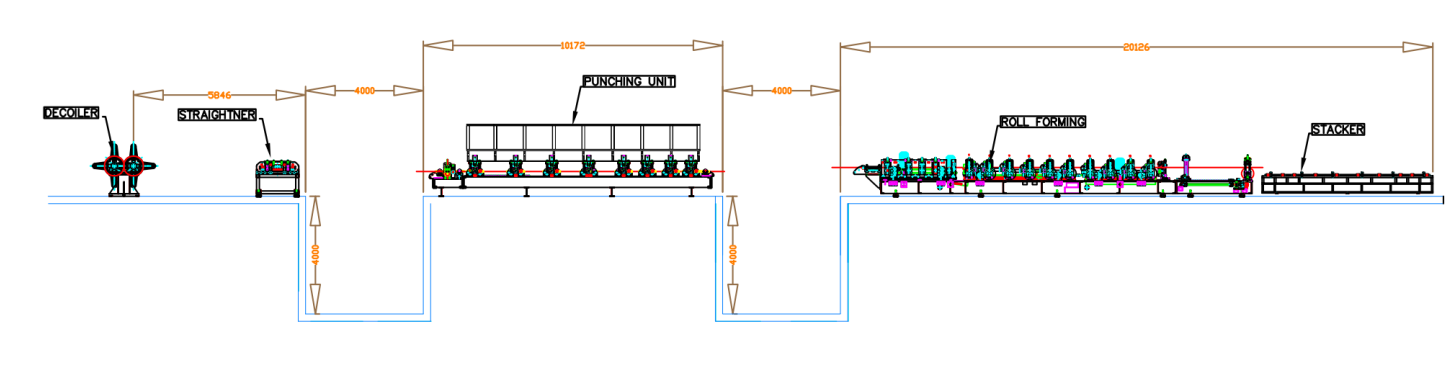

Full line working process

coil→leveling→in line punching→roll forming→high speed non stop cutting→auto stacker

Product Details

Full line adopt HIGH SPEED non stop working, without punching line speed up to 50m/min, include punching line speed up 35-40m/min, this greatly increased capacity and saved labor!

To save cost and factory space, we give QUICK CASSETTE design, one machine can make different section, just change some forming station.

Main Technology

2&3 waves barrier is one of main component of Road crash barrier, one machine can make two and three waves profiles, it only need to change 3 forming stations. The machine is with high speed, one minute can produce three products with punching. The whole line adopts servo motors to make the machine more accuracy and efficiency.

Main technology

• Heavy duty uncoiler with coil car

• Full coil and pinch system

• Full automatic high speed on line punching

• By cassette design two waves change to three waves

• Non-stop high speed cutting

• Full automatic stacking and packing

Main spec. of line:

• Full line power: about 140KW

• Full line speed: 12m/min

• Forming station: about 18 stations

• Drive by gear box of each station

• Full line weight: about 40Tons

• Roller material: D3

• Punching die and cutting die material: D2

• Motor: ESTUN servo

• Full line uses motion controller (MC4N-ECAT P901) and a remote control system

Layout for reference: