Storage Shelving RFM

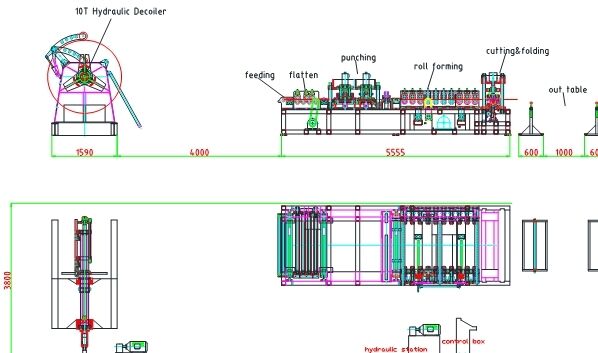

Saibo science & technology provide different type of shelf panel design. The main working process is coil→feeding→leveling→punching hole→notch→roll forming→cutting & bending→end product.

All of the width is adjustable by automatic.

Description

Product Detail

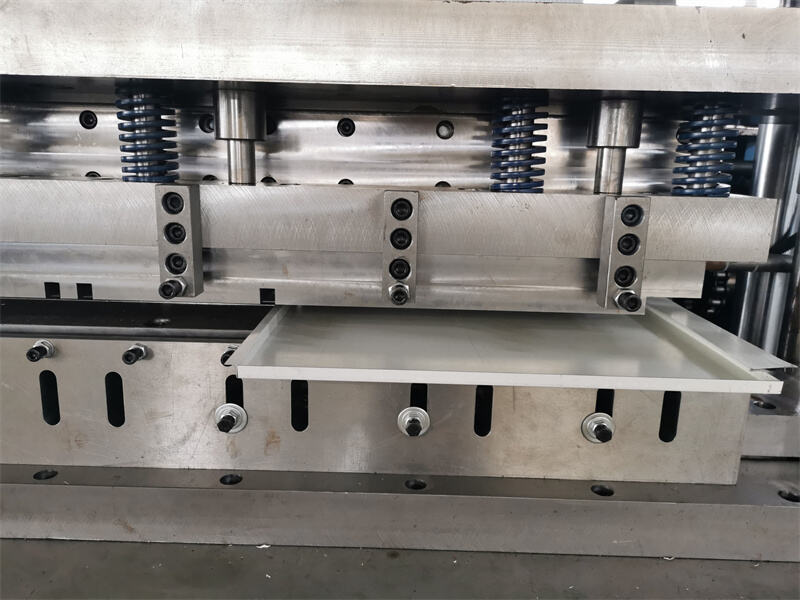

Shelf panel roll forming machine is one of main component of Warehouse selective pallet racking. Saibo science & technology provide different type of shelf panel design. The width can be adjusted by PLC. The punching position can be adjusted by hand wheel.

Main technology

Heavy duty uncoiler with coil car

Full automatic to make holes and notch on line

Full automatic change size

Full automatic cutting and folding

Main spec. of line:

Full line power: about 20KW

Forming speed: 0-20m/min

Forming station: about 10 stations

Drive by gear box or chain

Full line weight: about 10-15Tons

Roller material: GCR15

Punching die and cutting die material: D2

Motor: Siemens

Servo and control system: Mitsubishi/ Siemens/Panasonic

Layout for reference: