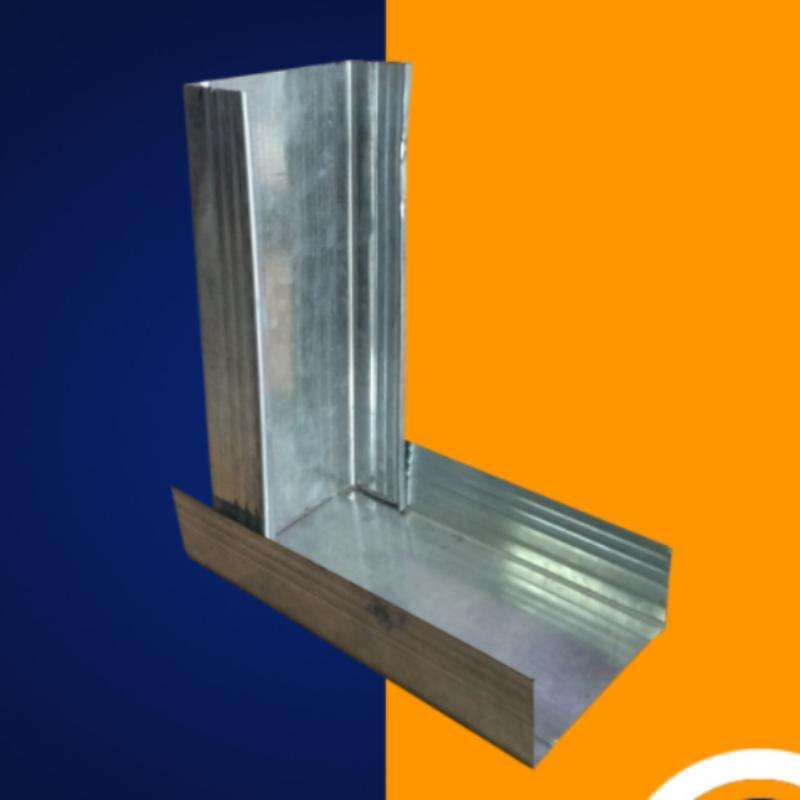

Stud &track for ceiling

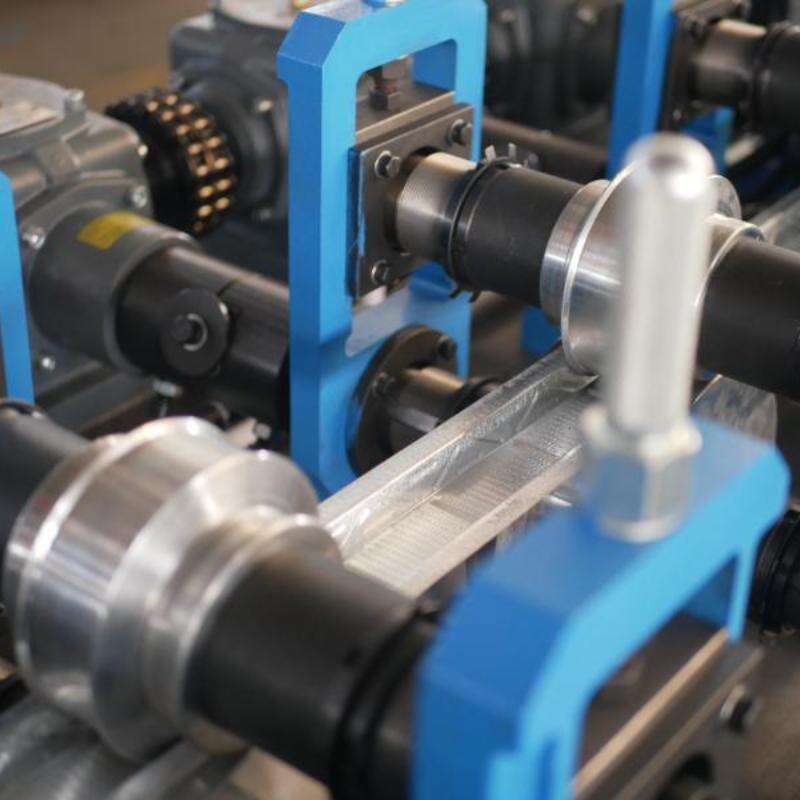

This machine is fully automatic and high speed producing continuously, one set of forming rolls can produce various sizes of Stud and Runner just by simply and easily changing the spacers, this enables the production of different sizes products on the same rollers.if want more fast can change the forming by cassette design.

Description

This machine is also can be designed for in line punching, punching and cutting in one time. Main motor use AC servo motor with inverter, producing in line speed: 60 meter per minute, quick or slow speed can be adjusted freely. After roll forming, automatic in line punching and cutting continuously. Cutting length: from 3 meter to 6 meter or more, length tolerance: within ±1mm. Automatic products piling table is special designed for high speed production capacity and reduce the production cost, create more profit for the customers.

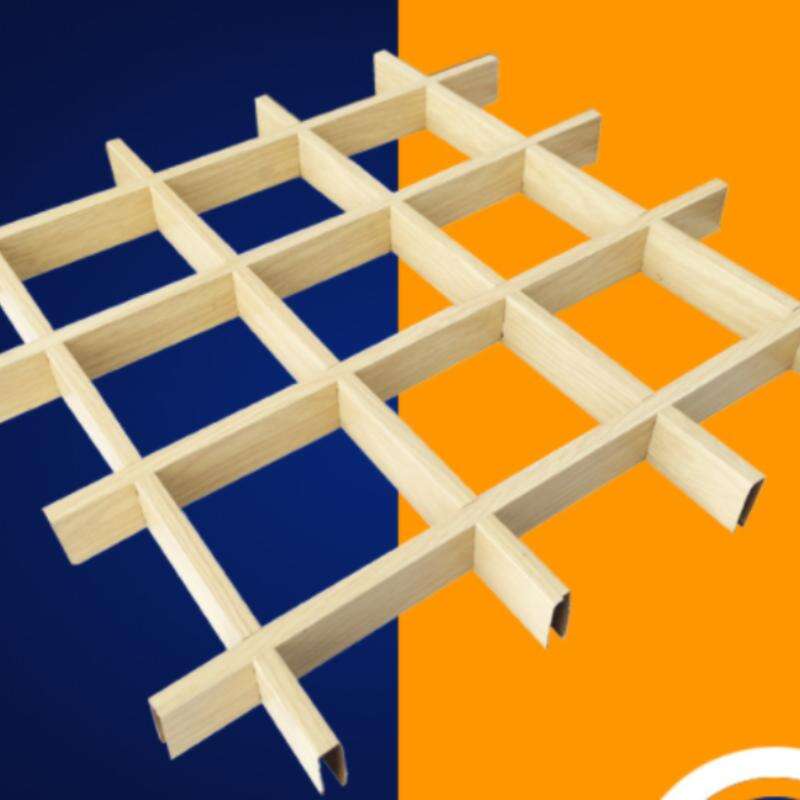

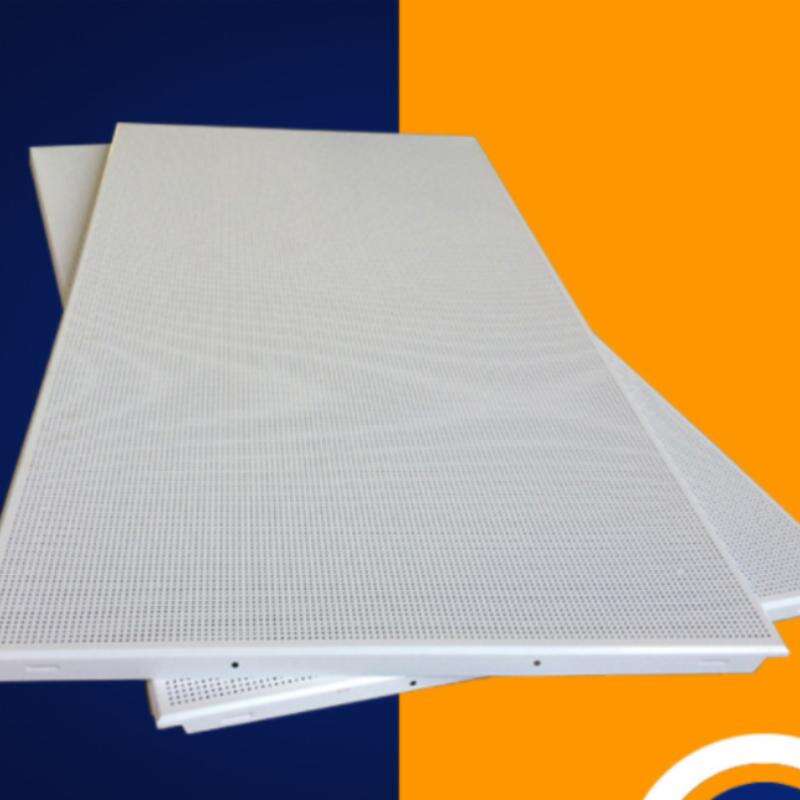

We not only provide Stud/track and different shape profile machine, also can provide the ceiling panel sheet machine.

Product Detail

Stud& track for ceiling is fully automatic and high speed machine, Saibo science & technology currently able to achieve a maximum speed is 80m/min. and has high degree of automation, can adjust the roller thickness by servo motor at the same time. Machine can produce different profiles according to customer request, to save cost, just change the spacers on the shaft, to save the time, can make the cassette type for change.

Main technology

Double head uncoiler for quick change coil

Full automatic change size

Full automatic adjust the roller distance

Non-stop high speed punching and cutting

Full automatic stacking and packing

Main spec. of line:

Full line power: about 25KW

Full line speed: 60m/min

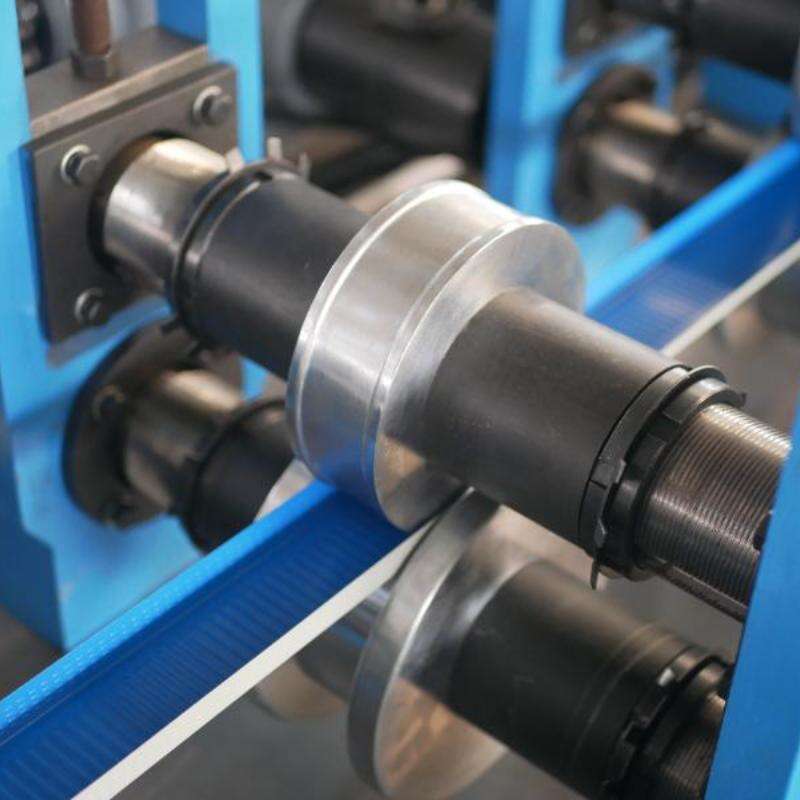

Forming station: about 13 stations

Drive by gear box of each station

Full line weight: about 10-15Tons

Roller material: D3

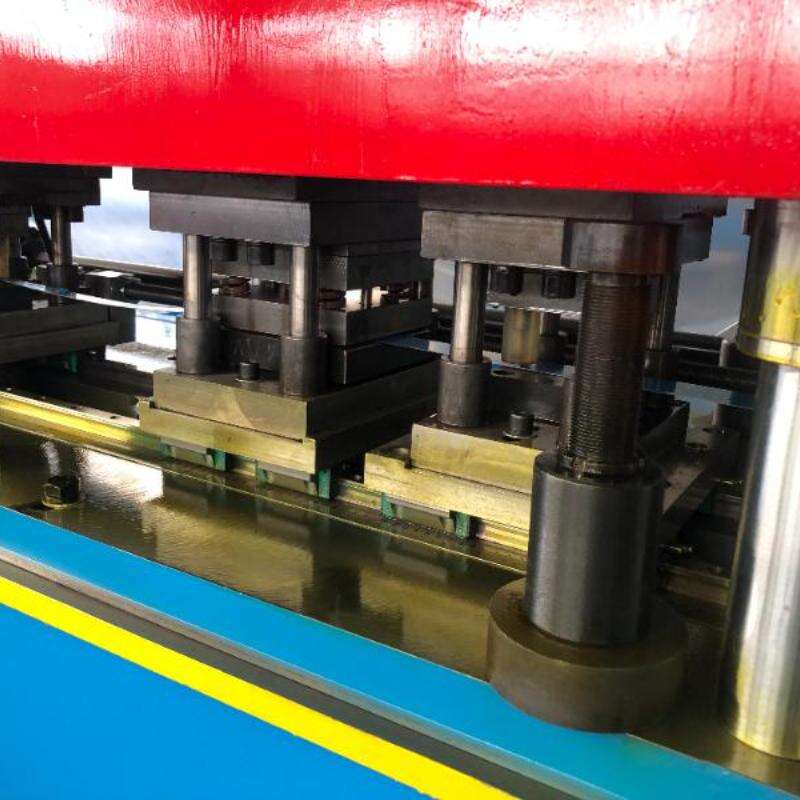

Punching die and cutting die material: D2

Motor: Siemens

Control system: Mitsubishi/ Siemens/Panasonic

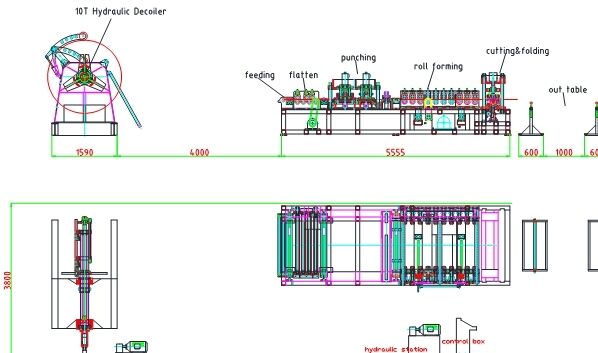

Layout for reference: