In China, numerous firms manufacture roll forming machines. These machines help form metal into various parts for buildings, cars and other stuff. Saibo is among the best manufacturers in this area. They make good machines that people trust. When shopping for a roll forming machine, you need to know what you are looking for. This guide is intended to show you how to select the right machine, review some problems with these machines and also how you can prevent those difficulties.

Purchasing Guide - How to Select the Proper Roll Forming Machine

Selecting the perfect roll forming machine can be a little bit hard. First, consider what you will use the machine for. Machines specialize in different types of work. If, for instance, you are fabricating metal panels for a roof, the machine must be capable of forming the metal sheets in the necessary curve and angle. There are various kinds of these machines, so you can choose one that best suits your needs with Saibo. Then think about the size of the machine. And if your workshop is small, a smaller machine may fit you better. But if you are producing a lot of products, a larger machine can allow you to work quickly. You may also want to find out how many pieces the machine can produce in an hour. This number can help you figure out how efficient your machine is. Another consideration is the machine itself. A well-constructed one will last you longer and save you money over time. Saibo is also renowned for manufacturing durable machines. Finally, consider the support you might require. And if something does go wrong, you want a company that can help you fix it fast. Saibo has an amazing support who will help and assist you if you have queries or require assistance.

Pressing Hard On Rollforming Problems And How To Avoid Them

Roll forming machines are wonderful, but occasionally they do go wrong. One common issue is misalignment. This occurs when the metal doesn’t feed straight through the machine. Erroneous alignment can cause parts to be non-square and not come together properly. To avoid this, make sure the machine is properly installed before using it. Align everything perfectly. Another problem is wear and tear of the machine components. Parts wear out, leading to the failure of the machine over time. Regular maintenance is important. Saibo advises regular inspection of the machine’s parts and replacing them as required. This should help the machine run smoothly and last longer. And occasionally, the machine’s not adjusted right. To calibrate is to be sure that the machine is working at its best. A machine can also not be calibrated and produce parts the wrong size. This can be prevented by following the calibration recommendations of the manufacturer. Finally, operators need training. If the person operating the machine doesn’t understand how to use it properly, errors can occur. Saibo provides user training to avoid such incidents. And that’s easy to do with a few simple steps which in turn maximize the life of your roll forming machine.

How Roll Forming Equipment Can Make Your Production More Efficient

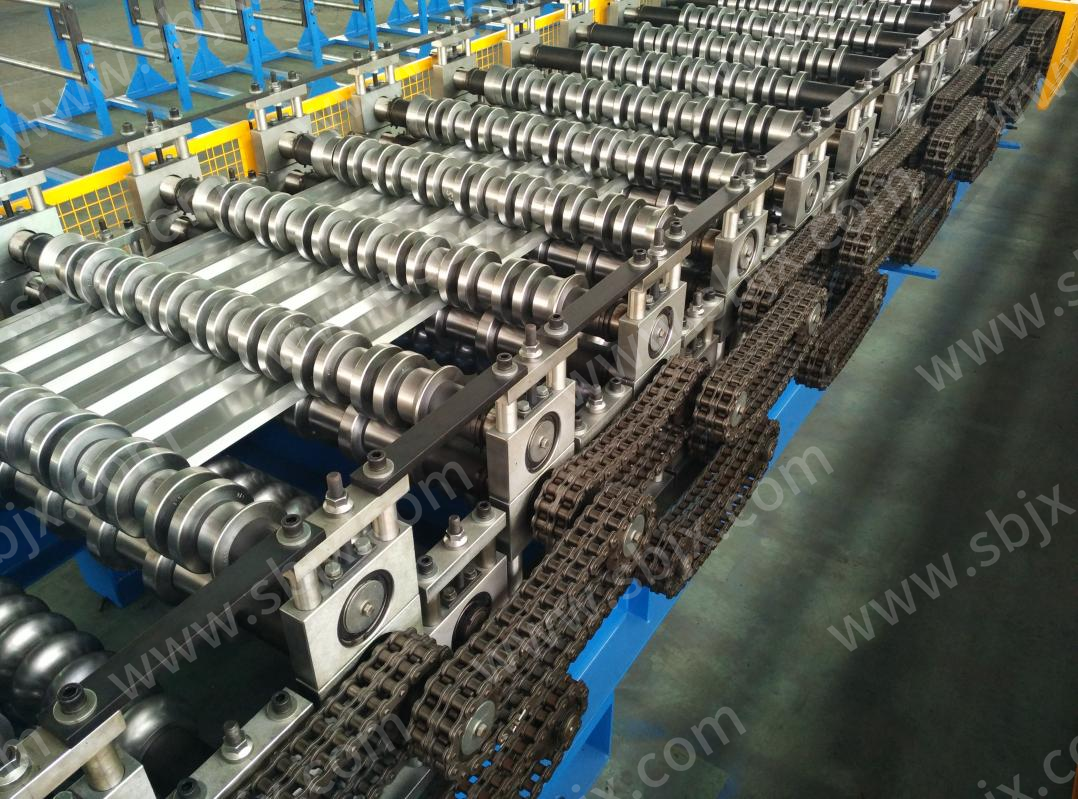

Roll forming machines are an important tool when a company needs to make metal products quickly and with precision. It operates by rolling a flat piece of metal into the desired shape with rollers. This is so efficient that companies can create long lengths of metal shapes with very little waste. With a company that has roll forming machinery, one can create an abundance of items in very little time. This enables them to respond more quickly to customer requirements and minimize downtime in their production lines.

One of the great things about roll forming is its ability to produce a large variety of shapes. Whether your requirement is as simple as an angle or a complicated serpentine shaped piece, roll forming can take care of it. This flexibility allows businesses to create numerous products, large and small from construction materials to machine parts. Since it’s so versatile, companies that use roll forming machines ultimately discover how to easily diversify their line of products.

What's more, roll forming equipment is cost efficient. Conventional manners of producing metal parts can be slow and produce a good deal of waste. Roll forming also minimizes waste by more efficiently using the metal. Reducing waste also allows companies to save on material costs. On top of that, faster production times allow businesses to produce more in the same amount of time and thus allows them to make more money.

Saibo develops machines such as our roll forming equipment that has been designed for the specific needs of the customer to deliver quicker production. They are famous for their speed and dependability of machines. Companies who decide on Saibo roll former can rest assured they are getting excellent efficiency combined with minimal downtime. That is, they can operate as effectively and distribute goods to customers as quickly as possible. At the end of the day, roll forming equipment is not only going to allow your business to produce more product in less time, but increase overall efficiency and profitability as well.

Where to Find Low Cost Roll Forming Machines for Your Operations

If you are in business and need a roll forming machine, you probably want to find the cheapest price available. There are plenty of locations where businesses can try to track down these machines. Begin one of the best places is online. There are many online platforms that carry manufacturing equipment. Roll forming machine All of these sites usually have around 5-15 roll forming machinery available at any time and in varying price ranges. By comparing costs and attributes, companies can find the machine that is most appropriate for their budget.

It also helps if you can attend industry events/trade shows. These shows allow companies to witness a variety of roll forming machines in operation. They can talk with manufacturers directly and get a sense of what each machine is capable of. This is a kind of hands-on experience that can be extremely helpful in decision-making. And, trade shows commonly offer special discounts or promotions so, you can find an even better deal.

Local manufacturers and distributors also serve as a great resource for the cheap roll forming machines. By working with these suppliers in the right manner, companies may be able to receive a better or at least more favourable price and terms. They might also have a service or training component, which could be a value add to the purchase.

Saibo's Roll Forming Equipment that pays close attention to quality which translates into excellent prices for all types of roll forming machines. They know companies must cut costs without cutting corners on quality production. Companies can tap dependable machines for that added edge without having to gamble. The business is no different than any other; with the proper research it's possible for businesses to find lower cost roll forming machines that will lead to success and growth.

What Sets a Roll Forming Machine Manufacturer Apart?

There are a number of things that can distinguish one roll forming company over another. For one, the quality of the machines is important. Because a strong manufacturer makes machines that withstand drive, part of that is not necessary. Which is essential for maintaining the flow of production, since there are fewer breakdowns and repairs. A provider such as Saibo is the best in quality machines so that users get only dependable ones.

Also important is the quality of customer service. Great support from a manufacturer also can make it easier for businesses to get help when they need it. This may involve answering questions, training and assisting with repairs. So you see, while the machinery is capable of lasting a long time and functioning well under most all conditions, customer service can be another matter altogether. When a putative manufacturer is both responsive and helpful, it inspires trust and satisfaction.

And innovation is the other part the distinguishes manufactures. A company investing in research and development also makes better, more effective machines. They seek places to better their products, rendering them faster and efficient. Companies like Saibo are able to deliver the constantly updated technology on the machines as they evolve in accordance with what is going on today, adapting them according to both industry standard and customer requirements.

Finally a good reputation in the field matters. When a brand is renowned for its reliable and responsive machinery, in addition to stellar customer support, it becomes the considered option of more companies. Good reviews and recommendations from past customers are another way to help people feel good about their purchase. Saibo has established itself as a reliable choice for businesses looking to invest in roll forming machines. So to sum up, Quality, customer service, innovation and reputation can all separate one roll forming equipment manufacturer from another.

Table of Contents

- Purchasing Guide - How to Select the Proper Roll Forming Machine

- Pressing Hard On Rollforming Problems And How To Avoid Them

- How Roll Forming Equipment Can Make Your Production More Efficient

- Where to Find Low Cost Roll Forming Machines for Your Operations

- What Sets a Roll Forming Machine Manufacturer Apart?