As the top quality machine manufacturer in China, we always strive to provide customers with complete building systems.We provide workshop, warehouse, residential doors, door frames, rolling shutter doors, window linings, etc.

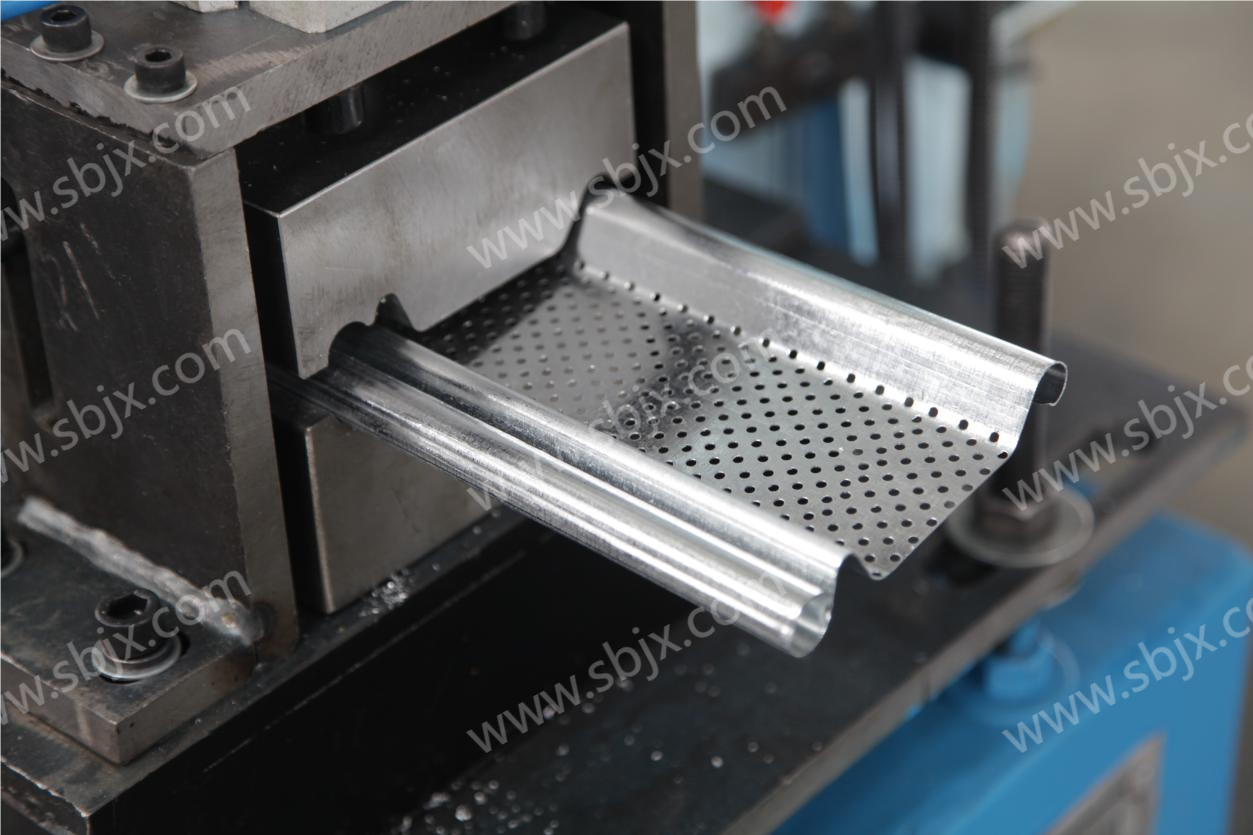

We provide single/double frame door machine, All automation on the machine, such as in-line punching keyhole, hinge hole, muffler hole, etc., complete 45°and 90° shear simultaneously. After the machine production, you can directly assemble a complete door frame.

Is there a problem? Please contact us to serve you!

As the top quality machine manufacturer in China, we always strive to provide customers with complete building systems.We provide workshop, warehouse, residential doors, door frames, rolling shutter doors, window linings, etc.

We provide single/double frame door machine, All automation on the machine, such as in-line punching keyhole, hinge hole, muffler hole, etc., complete 45°and 90° shear simultaneously. After the machine production, you can directly assemble a complete door frame.

For shutter door,It also has many kinds of structure, such as single-layer steel rolling shutter door, polyurethane foam rolling shutter door, attracting rolling shutter door and so on. Saibo Science & Technology is working hard in developing in optimal design and the most perfect structure.

PEB is a very complex system, which consists of a large number of different components, each of which is very important. And what we do is we help our customers and give solution.Door frame and shutter is one is one of very component in PEB project, it have many different design, like single frame/double frame/single layer shutter/double layer shutter or PU foam shutter and so on.Saibo science and technology can give many different design, and very important is that we can give customer by their request.

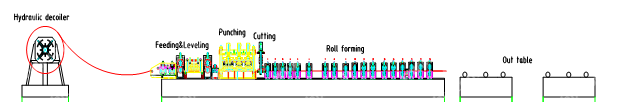

Main technology

Single head or double head uncoiler with coil car

Full automatic set request length and quantity

Full automatic to make all holes on line

By cassette design one machine can make different profiles

Hydraulic no scrap cutting

Full automatic stacking and packing

Main spec. of line:

Full line power: about 10-30W

Forming speed:0-30m/min

Forming station: about from 15-35tations

Drive by gear box or chain

Full line weight: about 6-25Tons

Roller material: GCR15

Punching and cutting die material: D2

Motor: Siemens

Servo and control system:Mitsubishi/Siemens/Panasonic......

Different design Layout for reference: