Q: What is the price of the roll forming machine?

A: The price of the equipment depends on various factors such as profile specifications, thickness, and additional features. Could you please provide us with more details about your specific requirements, so we can provide you with an accurate price.

Q: What is the warranty period for the roll forming machine?

A: We offer a standard warranty period for our equipment, which typically ranges from one year. However, the exact warranty period may vary depending on the specific equipment model. We can provide you with detailed information regarding the warranty coverage for the equipment you are interested in.

Q: Are spare parts readily available for the equipment?

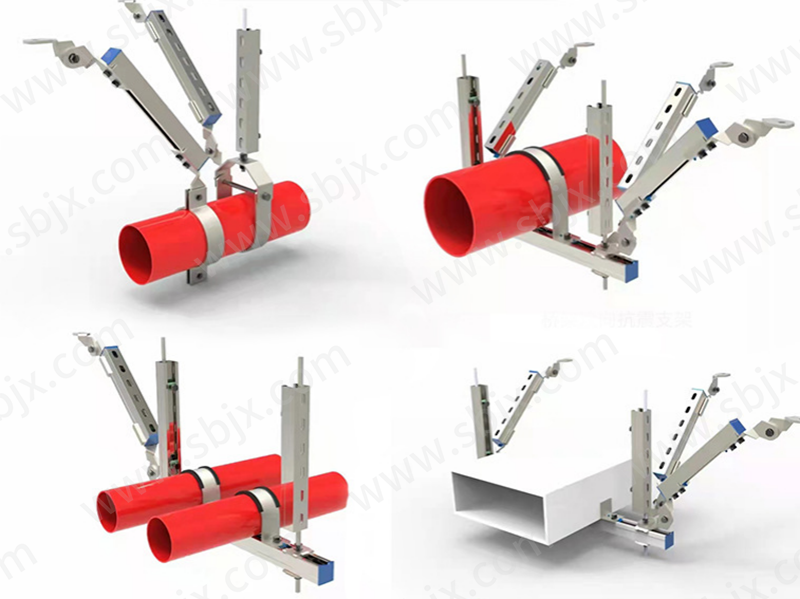

A: Yes, we ensure that spare parts for our equipment are readily available. We maintain a comprehensive inventory of spare parts to minimise downtime in case of any maintenance or repairs. Additionally, we offer after - sales support and can assist you in procuring any necessary spare parts for a roll forming machine, such as a rolling shutter forming machine, decking sheet roll forming machine, Stud and Track roll forming machine, and so on. Sure, like some rollers need for product depend on order only, it will be 3 - 7 days. We will try our best give you early.

Q: Can you provide training for operating the equipment?

A: Yes, we can provide comprehensive training for operating the equipment. Our team of experts will guide you through the installation process and provide hands - on training to ensure that you and your staff are familiar with the equipment's operation, maintenance, and safety procedures.

Q: Is installation included in the purchase price?

A: The inclusion of installation services may vary depending on the specific equipment and the location of the installation. We can discuss the installation options available and provide you with a detailed quotation that specifies whether installation is included or if it will incur additional charges.

Q: Do you offer customization options for the equipment?

A: Yes, we do offer customization options for our equipment to meet specific customer requirements. We can discuss your customization needs and work closely with our engineering team to develop a tailored solution that suits your unique application.

Q: What is the expected delivery time for the equipment?

A: The delivery time for the equipment depends on various factors, including the availability of stock and the complexity of customization, if applicable. Once we have a better understanding of your requirements, we can provide you with an estimated delivery timeframe. But as standard will be about 45 - 60 days with depend on quantity request.

Q: Can you provide references or customer testimonials for your equipment?

A: Certainly! We can provide you with references or customer testimonials upon request. Our satisfied customers can share their experiences and provide insights into the quality and performance of our equipment.

Q: What after - sales support do you offer?

A: We offer comprehensive after - sales support to ensure the smooth operation of the equipment. This includes technical assistance, troubleshooting, and maintenance services. We have a dedicated support team that can address any queries or concerns you may have even after the purchase.